|

|

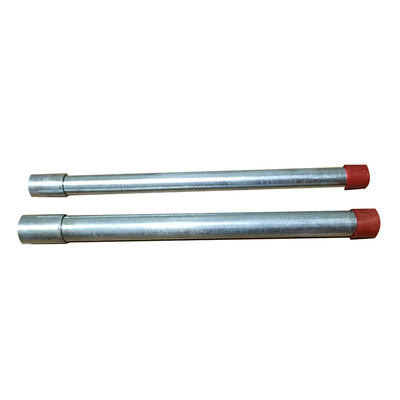

Hot Dip Glavanized Gi Conduit Pipe BS4568 Certificate 1.80MM Thickness

Product Details:

Payment & Shipping Terms:

|

| C/W: | Socket & Plastic Cap | Material: | Carbon Steel Coil |

|---|---|---|---|

| Type: | Class 3 &Class 4 | Size:: | 20mm To 70mm |

| Color: | Gray White | Thread: | BS4568 Standard |

| Thickness: | 1.25mm To 1.60mm | Cerficate: | BSI Kitemark |

| Highlight: | 1.80MM Thickness Gi Conduit Pipe,Hot Dip Glavanized Gi Conduit Pipe,BS4568 Certificate Gi Conduit Pipe |

||

1-1/2" Class 4 Conduit Pipe Hot Dip Glavanized BS4568 61386 Certificate 1.80MM UK Standard

20MM TO 50MM CLASS 4 BSI KITEMARK Certified With Test Report

General:

Steel BS4568 G.I. conduit is manufactured from a mild steel tube,It has an accurate circular cross section,a uniformand wall thickness,a defect free interior surface.The finished threads,BS4568,conforms to the BS4568 Part 1:1970 BS EN BS EN 50086-1:1994 & BS EN 61386,Each length of the conduit have the size,logo,product name print or engraved to make as installation instructions

Application:

Ranlic BS4568 conduit can be installed indoors or outdoors,in dry or wet locations,exposed or concealed,in all kinds of atmospheric conditions if use the standared thickness,the galvanized thickness exceeding 70 micro meter.it provides excellent mechanical protection for the conductors while reducing Electro-Magnetic Field exposure and shielding.

Features:

Q195 steel coil for mechanical strength,well controled internal beads(all can remove as seamless) essential for wire pulling and resistant to snagging The conduits are come with a coupler screwed on one end and a protective plastic cap at the other ends to prevent damage.Rigorous quality control procedures to ensure process and product consistency

- Galvanized steel construction provides shielding from magnetic fields and protection from impact damage and crushing

- Electroplated couplings prevent zinc build-up

- Designed for use with threaded connections

- Brand Name: RANLIC

- Length : 3.75 meters.

- Material : Galvanized steel-class 3 / Hot-dipped Galvanized-class 4

- Size: 3/4” , 1" , 1-1/4”

- Thickness: 1.3mm---1.6mm or according to customer's requirement

Characteriestic & Diamention:

| NORMAL | ITEM No. | OUTSIDE DIAMETER | NORMAL | THIN WALL | LENGTH W/O | SMALL | BIG | ||

| SIZE | MIN | MAX | THICKNESS | THICKNESS | COUPLING | PKG (LGTHS) | PKG (LGTHS) | ||

| 20mm | RL15-20-3 | 19.7mm | 20.0mm | 1.6±0.15mm | 1.30mm | 3.75 meters | 10 | 100 | |

| 25mm | RL15-25-3 | 24.6mm | 25.0mm | 1.6±0.15mm | 1.30mm | 3.75 meters | 10 | 100 | |

| 32mm | RL15-32-3 | 31.6mm | 32.0mm | 1.6±0.15mm | 1.45mm | 3.75 meters | 10 | 50 | |

| 38mm | RL15-38-3 | 37.6mm | 38.0mm | 1.8±0.15mm | 1.60mm | 3.75 meters | 5 | 30 | |

| 50mm | RL15-50-3 | 49.6mm | 50.0mm | 1.8±0.15mm | 1.60mm | 3.75 meters | 5 | 30 | |

| 63mm | RL15-63-3 | 62.5mm | 63.0mm | 2.1±0.15mm | 1.80mm | 3.75 meters | 1 | 10 | |

| 70mm | RL15-70-3 | 74.5mm | 74.0mm | 2.1±0.15mm | 1.80mm | 3.75 meters | 1 | 10 | |

![]()

Why Choose Ranlic Conduit Item:

1) High quality material ensures a finish conduit and fittings with superior properties

2) Manufactured by perfect molds and professtional engineer

3) Fitted perfectly with fittings(conduits) for the CNC threading machine

4) 10 years export experience to make sure the perfect shipment date and package

5) Always like to listening customers feedback for the conduit arrived to

customer's warehouse to improving our service

Our Package:

![]()

General:

BS4568 Part 1:1970 BS EN BS EN 61386-1:1994 & BS EN 61386,Steel BS4568 G.I. conduit is manufactured from a mild steel tube,It has an accurate circular cross section,a uniformand wall thickness,a defect free interior surface.The finished threads,BS4568,conforms to the,Each length of the conduit have the size,logo,product name print or engraved to make as installation instructions

Hot Dipped Galvanised to Class 4

AXWILL Class 4 conduit is Hot Dipped Galvanised, a process where steel products are coated with zinc by immersing them in a molten zinc bath at a temperature of approximately 450 °C. Trace elements of alloying metals such as lead, aluminium and nickel are included to improve fluidity and reduce dross. The alloys also assist in producing a bright silver appearance which becomes dull grey when exposed to the atmosphere. Hot Dipped Galvanising creates a proactive and self-repairing corrosion resistance; zinc reacts in the air and forms zinc carbonate (responsible for the dull grey in appearance), which protects the steel from corrosion.

Barton Class 4 conduit is routinely inspected for corrosion, strength and bending and is independently tested by an approved laboratory.

Handling and Storage

Galvanised conduit should be stored in dry conditions with good air circulation to prevent wet stain storage ("white rust"). However, should this occur it can be easily removed and does not affect corrosion resistance.

Binding materials used to make up bundles of conduit are not intended to be used when lifting this product, which should be handled only with approved slings.

-

Class 4 GI Conduit Pipe Thickness 1.60mm Fix With Coupler Cap BSI Certified

-

Hot Dip Galvanized GI Inspection Bend 25mm 32mm BSI Kitemark Certified

-

Female Threaded GI Conduit Elbow Hot Dip Galvanized 25mm 32mm For Bend Cornor

-

Electrical BS31 Gi Conduit Pipe Class 3 3/4" 1-1/2" Pre Galvanized

-

BSI Certified Gi Conduit Pipe 20mm 50mm With Coupler End Cap

-

Class 4 25mm GI Conduit Class 4 Galvanised Electrical Conduit For Project Directly